-40%

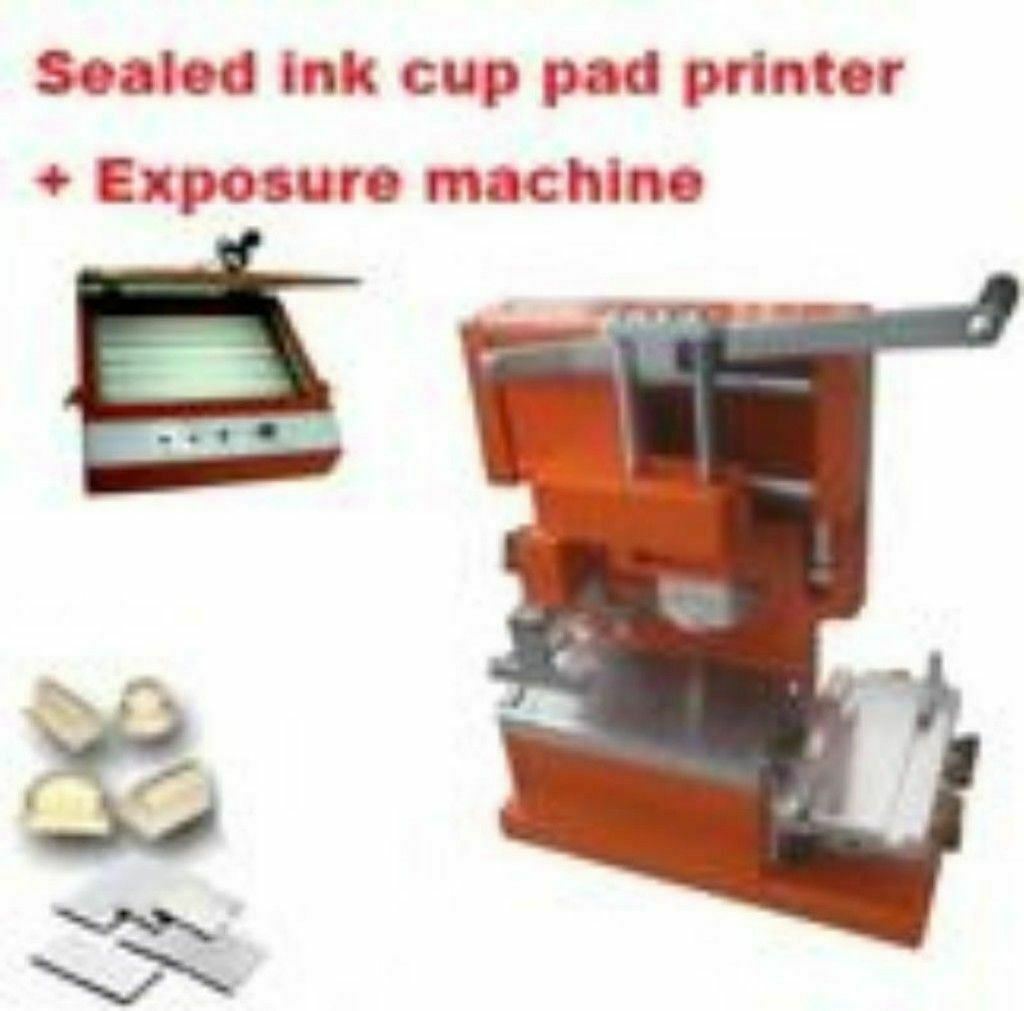

Manual ink cup pad printer + Polymer plates making package Business start kits

$ 380.16

- Description

- Size Guide

Description

Manual Sealed inkcup pad printing printer + plate making kits packageManual pad printing printer package:

(One stop solution to pad printing, you only need buy the pad printing ink to start up the pad printing ! )

Including:

Manual inkcup pad printer, 1 piece

UV Exposure machine ( Plate maker ), 1 piece

Cliche Making Polymer

Plates, 2 pcs

Rubber Pads , 2 pcs

A4 size Transparent films, 5 pcs

( for injet printer or laser priter uses )

The pad printer is

last one

, and was put in warehouse for three years, and

look dirty,and one part is broken

,but we check it, this is

good condition

, and the printer is manual, there is no any electric parts,so you can use it for

a life time

.

If you want it, we can

refund you 0

.

Pad printing

's biggest advantages are the ability to print on irregular surfaces, such as golf balls, lighters, pens, bottles, toys,etc, on small areas image printing. It can also print on flat surfaces.

Pad printing

is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset printing process that involves an image being transferred from the printing plate (cliché) via a silicone pad onto a substrate (surface to be printed). Pad printing is used for printing on otherwise impossible products in many industries including medical, automotive, promotional, apparel, electronics, appliances, sports equipment and toys.

Advantages of

Photopolymer Plates

making:

1.

Good for the environment

, no need chemicals.

2.Make clich making process easier to operate.

3.Save money for you, no need of chemicals and no steel coating machine.

This package uses: Photopolymer Plates

The plate material is UV photosensitive and when exposed to an ultraviolet light through a high contrast negative, the U.V. cross links the polymers and hardens the image.

The unexposed portion of the negative is washed off in plain water, dried and post exposed.

the plate is ready for the press in less than thirty minutes.

1:Pad Printer (sealed ink cup), ONE Unit

TECHNICAL PARAMETER:

Max printing area 80×

80mm

Steel plate size 100×

100mm

Max workpiece length

150mm

Level stroke

100mm

Pad vertical distance

60mm

Printing speed 400pcs/hr

Out dimension 400×200×500mm

Machine net weight

27kg

Free two pads (one square and one round)

2: UV Exposure plate maker,

ONE

Unit

Main features:

User-friendly desktop design with long-term life span

Parameters.

6 UV fluorescent tubes

Exposing area:

10.23"x8.26"(260x210mm)

Voltage: 110v/220v

Light power: 48W (8W x 6 tubes)

Time Range: 0-5.5 mins

Machine size:11.82"x11.8"x29.5"(30x29x75cm)

Net weight: 12Lb(5kg)

3: Cliche making Polymer plates:

2 sheets

Size: 100mm x 100 mm

Providing a good do-it-yourself option. These are typically used in short to medium production runs.

Water washable No solvent used!!

High durability, Allows printing very fine lines and big solid lines together, by using 300 lpi screen available.

High Reproductivity

Cost Effective

4:Transparent films:

5 SHEETS

( for ink-jet printer or laser priter uses )

Any Epson/HP/Canon ink-jets printers can use it.

This Film is a specially coated,clear film that absorbs quick drying inkjet ink, and controls the shape of fine lines and half tones,can be used to make stencil in screen printng,hot stamping and pad printing.Ink-jets achieve better quality.

Print on the coated (matte) side of the film!

For the unique high-tech solution, they can not be conglutinated with each other when folded together. The image is well-resisting and suitable for storage.

Note 1: This film also can be used in your laser printer

Note 2: Your wet finger will stick to the coated side.

Note 3: Printing side is the non-smooth side

A4 8"x12" (210x297 mm)

Pad Printing Polymer Plate Making Process

1.Contact with Positive film

Remove cover film slowly and place positive film onto undeveloped plate.Keep the positive film contact with the plate tightly.

Use positive film having optical density of not less than 3.0.

2.Exposure

Put the plate covered with film on the glass of the UV exposing machine. Expose plate, through positive film, to UV light having 360 nm wave lengths for 1-2 minutes.

3.Wash-out

Remove positive film.

Wash-out exposed plate with water, at 15-25 degree for 1-2 minutes. You can use a sponge roll or very soft brush. If wash out unit is not available, you can wash it out with running tap water.

4.Drying

Dry the plate in a hot-air dryer after removing the surface water by sponge roll(or soft brush) at 50-70 degree for 5-10 minutes.

5.Post exposure

Expose the dried plate to UV light again for 15-20 minutes in order to get stability.After post-exposing, the plate will become hard enough to be suitable for printing.

General Hints:

Gloss film as well as matted film can be used.

Good contact between film and plate is essential.

Treat films carefully as any kink will be reproduced on the developed plate.

Check film and plate without any dust before exposure.

Minimize the pressure of doctor blade to enjoy longer durability of plate.

It can be used in inkwell system and closed ink cup system.

inkfrog terapeak

Listing and template services provided by inkFrog